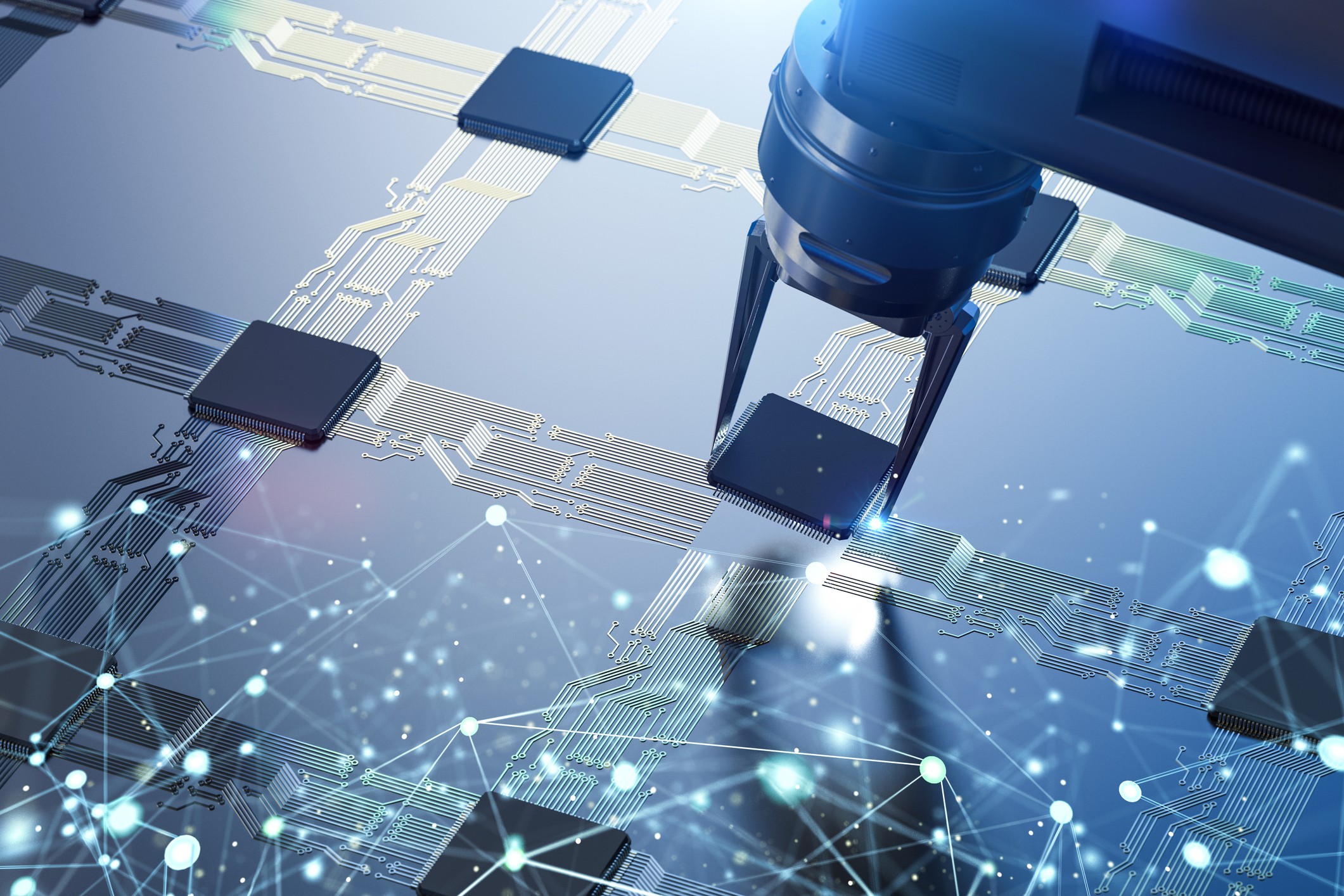

Humatics Microlocation

for The Semiconductor Market

40 microns of accuracy for 2D use cases

Automate applications previously not possible

Improve quality, yield, production speed and profitability

Mobile robotics introduce a new level of automation to the semiconductor manufacturing market. Radio frequency microlocation technology enables the use of disparate robotic systems to very accurately control the placement of different types of semiconductor products while sharing location data into any digital twin environment. The result is improved processing that can significantly cut labor requirements while increasing yield and profitability.

Humatics Microlocation Advantage

Precise Control of Robotic Systems for High Value Results

Microlocation allows two independent robotic systems to work concurrently on an engine as it traverses a pitch.

The robotic arms are guided with sub-millimeter precision to achieve real-time fine grain control to facilitate in-motion bolt torquing

Systems can remain independent

The robotic arms are not required to interact enabling each to achieve their function independently from the other reducing complexity, development time and cost

Support dynamic motion

Even as an engine moves in multiple directions the Microlocation system can guide the robotic arm to the exact location of the in-motion bolts to enable automation

Works well in various types of environments

Radio frequency works well in less than ideal conditions like smoke, low light, no light and obstructions such as surgical curtains

Integrates quickly into any system

Leveraging our RESTful API’s and our open data stream the real time positional data can be easily consumed for high value utilization by numerous systems

Accurate Location of Robotic Systems for High Value Results

Microlocation allows non fixtured mobile robotic systems to accurately interact with various work products in the same or different environments enabling full production automation.

In 2 dimensions (2D), the Humatics system can achieve 40 microns of accuracy. In 3 dimensions (3D) the microlocation system can achieve less than 1 millimeter of precision. The system delivers 121 positions per second

No Image Processing

Microlocation uses high frequency radio signals that are used to generate highly accurate position information. This eliminates the need for image processing delays that are required with vision systems.

Works well in various types of environment

Radio frequency works well in less than ideal conditions like semiconductor packaging environments. It is agnostic to lighting changes, color of clothing and other environmental variables.

Improve Yield, Profitability and Lower Labor Rquirements

Microlocation eliminates the need for intensive human interaction in environments that previously could not leverage mobile robotics, such as some types semiconductor packaging due to its dynamic nature. This enables workers to be assigned to more valuable tasks and to improve yield, productivity and product quality.

Microlocation Productivity Improvements for Semiconductors

Automation Improvements

A side by side comparison of the productivity speed improvement of human setup in semiconductor packaging versus a fully automate solution that is leveraging mobile robotics and Humatics Microlocation